How to Properly Install Acoustic Panels?

Acoustic panels are one of the most effective ways to improve room acoustics by reducing echo, controlling reverberation, and enhancing sound clarity. Whether you’re designing a recording studio, home theater, or office space, proper installation is just as important as choosing the right acoustic panels.

In this guide, we’ll walk you through the best practices for installing acoustic panels and explain why Guangdong Leeyin Acoustics is a trusted partner for premium wood slat wall panels and acoustic solutions.

🎯 Why Proper Installation Matters

Even the highest-quality acoustic panels won’t deliver their full potential if installed incorrectly. Proper placement and secure installation ensure:

-

Maximum sound absorption in critical reflection points

-

Balanced room acoustics without over-dampening

-

Aesthetic integration with interior design

-

Durability and stability over years of use

🛠 Step-by-Step Guide to Installing Acoustic Panels

1. Identify Reflection Points

Before installation, determine where sound reflections occur in your room. These usually include:

-

Walls beside and behind speakers

-

Ceiling above the listening or recording area

-

Back wall facing the speakers

👉 A mirror test can help: sit in the listening position and have someone move a mirror along the wall—wherever you can see the speaker, a panel should go.

2. Choose the Right Mounting Method

There are several ways to mount acoustic panels, depending on the panel type and wall surface:

-

Adhesive strips or Velcro (easy and removable)

-

Z-clips or brackets (for heavy wood slat panels)

-

Construction adhesive (permanent installation)

-

Freestanding or modular frames (no wall damage)

For wooden slat acoustic panels, we recommend using screws or concealed mounting systems to ensure long-term stability and a seamless appearance.

3. Measure and Mark Placement

Use a level and measuring tape to ensure even alignment. Consistent spacing not only improves acoustic performance but also enhances aesthetics.

4. Install with Spacing (Optional for Enhanced Performance)

For better low-frequency absorption, consider leaving a small air gap (2–4 cm) between the panel and the wall. This improves bass control without requiring thicker panels.

5. Check for Secure Fit

Once mounted, ensure panels are firmly in place. Loose or poorly secured panels may cause rattling or reduced effectiveness.

📌 Professional Tips for Best Results

-

Balance is key – avoid covering every surface; instead, treat first reflection points, ceilings, and corners.

-

Mix treatments – combine wall panels with bass traps and ceiling clouds for full-spectrum control.

-

Aesthetic integration – choose wood slat acoustic panels for a solution that blends modern design with acoustic functionality.

🏭 Why Choose Guangdong Leeyin Acoustics?

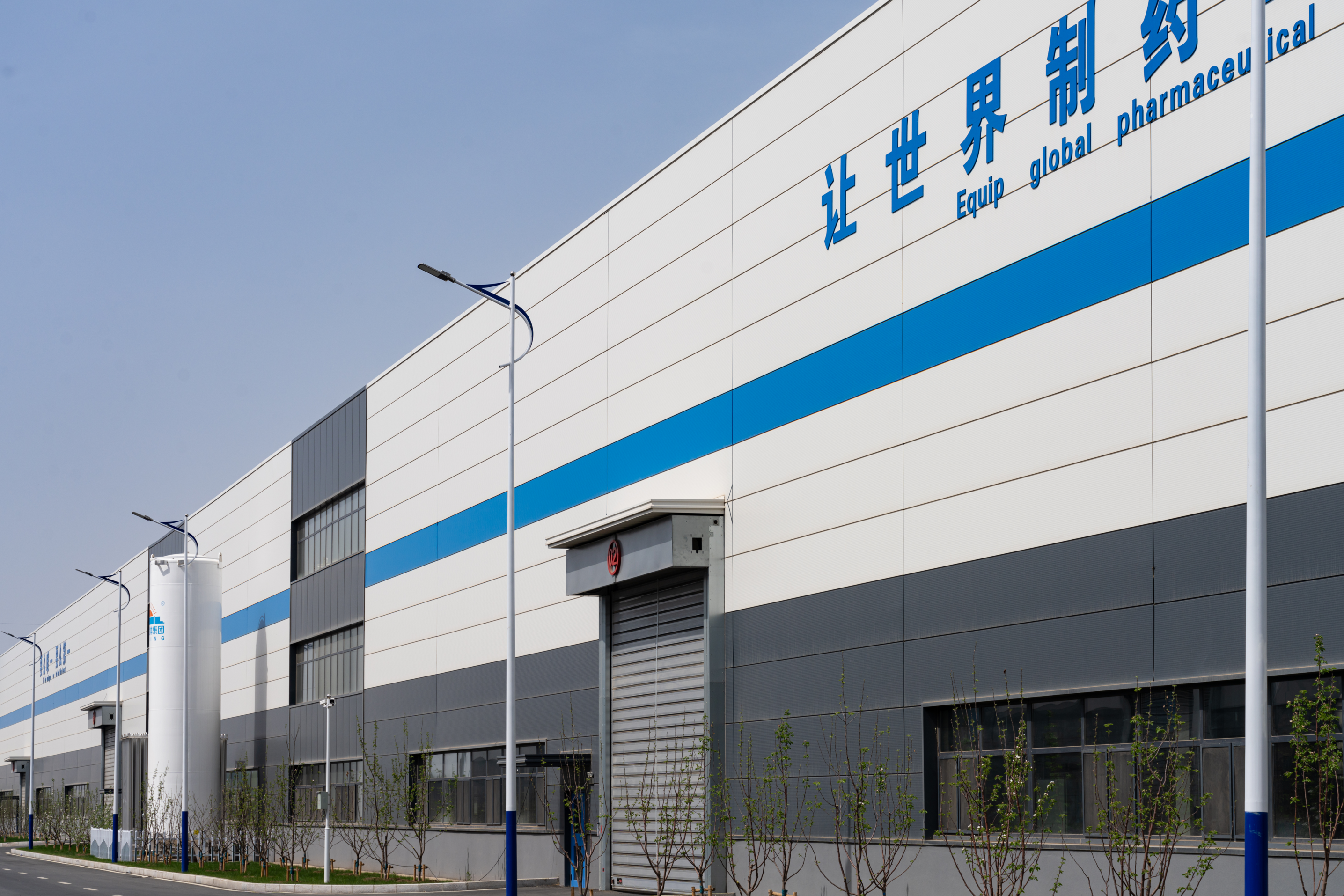

At Guangdong Leeyin Acoustics, we specialize in designing and manufacturing high-performance wood slat wall panels and acoustic solutions.

-

Industry leader – one of China’s top exporters of wood slat panels.

-

Advanced production – 20,000㎡ modern factory with state-of-the-art equipment.

-

International quality control – strict adherence to global standards.

-

Custom solutions – offering a wide range of finishes, sizes, and installation options.

Our panels are engineered not only for acoustic excellence but also to serve as architectural design elements, making them ideal for studios, commercial interiors, and luxury residential projects.