T Slot Aluminum: A Versatile Solution for Modern Construction and Manufacturing (AI-generated)

T Slot Aluminum: A Versatile Solution for Modern Construction and Manufacturing (AI-generated)

Introduction to T Slot Aluminum

T Slot Aluminum has emerged as a cornerstone in modern construction and manufacturing, thanks to its exceptional versatility and adaptability. This material is increasingly favored across diverse industries, from automation to DIY projects, due to its modular design and ease of use. Its unique structure allows for the creation of custom frames and structures without the need for welding or complex assembly processes, making it an ideal choice for both professionals and hobbyists.

One of the primary T Slot Aluminum applications is in industrial settings, where it is used to build robust workstations, machine guards, and conveyor systems. This adaptability is not only limited to industrial uses but extends to home improvement and DIY projects, where it is used to create customized furniture, shelving, and even home automation systems. Such versatility underscores its growing popularity among engineers and DIY enthusiasts alike.

Moreover, the growing trend of automation in manufacturing has further cemented the importance of T Slot Aluminum. Its ability to support complex automation systems while ensuring safety and efficiency makes it indispensable in modern industrial environments. This material's application in constructing ergonomic workstations and safety barriers highlights its role in enhancing productivity and safety in workplaces.

As industries continue to evolve, the demand for materials that offer flexibility, durability, and ease of assembly is increasing. T Slot Aluminum meets these needs, providing a reliable solution for creating strong, adaptable structures. Whether you are involved in large-scale industrial projects or small-scale DIY endeavors, understanding the uses and benefits of T Slot Aluminum can open up new possibilities for innovation and efficiency in your projects.

Detailed View of T Slot Aluminum Profile and Its Modular Design (AI-generated)

Detailed View of T Slot Aluminum Profile and Its Modular Design (AI-generated)

What is T Slot Aluminum?

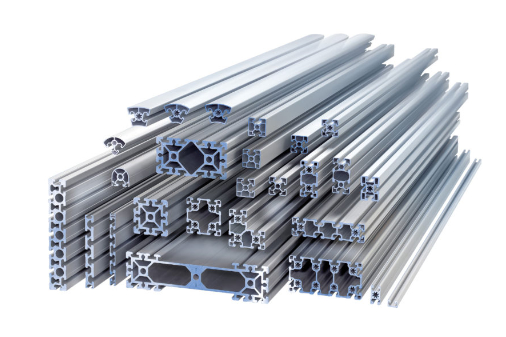

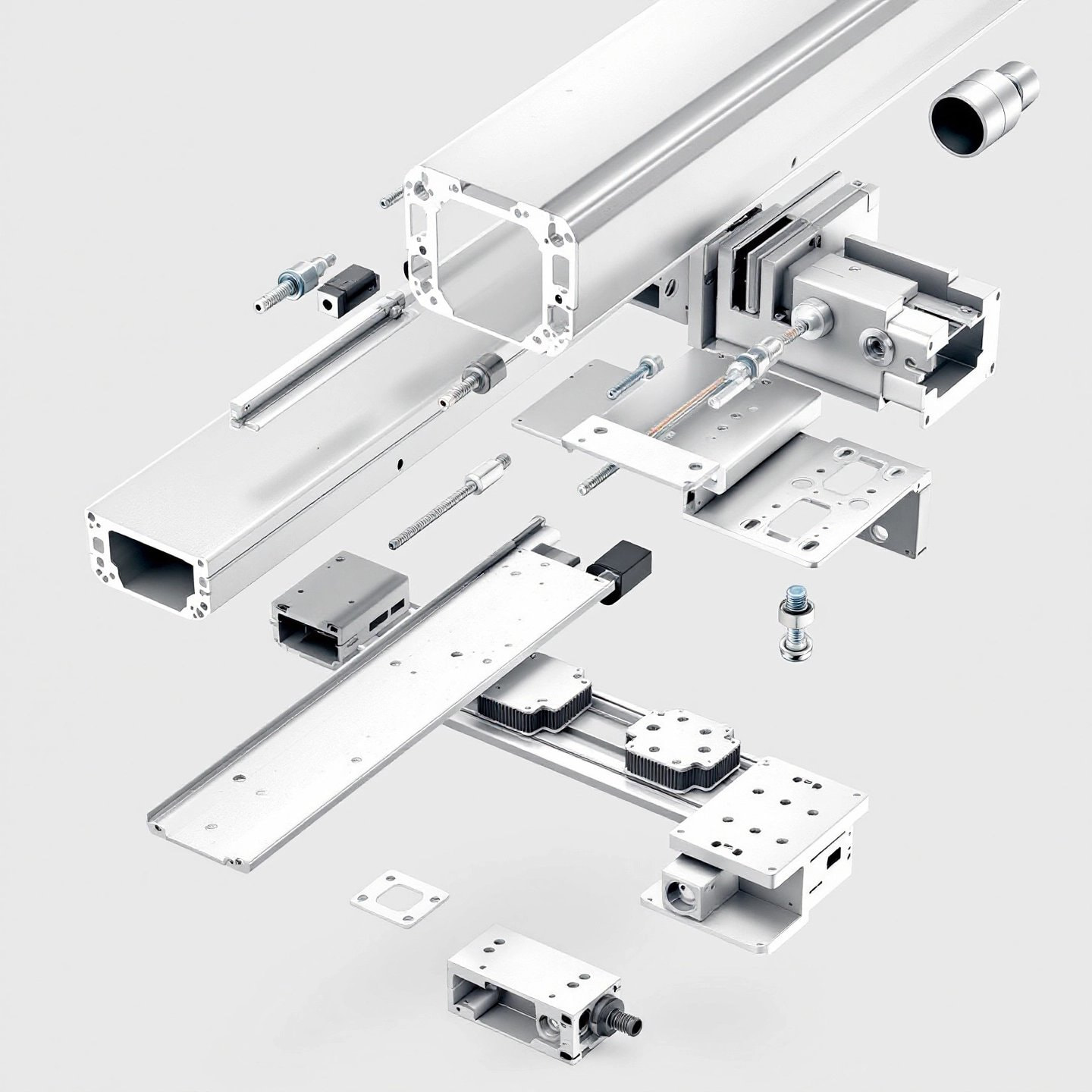

T Slot Aluminum is a revolutionary material that has transformed the way custom frames and structures are designed and assembled. At its core, T Slot Aluminum consists of extruded aluminum profiles that feature a unique 'T' shaped slot along one or more sides. This distinctive design is what sets it apart, allowing for unparalleled flexibility and ease of use in various applications.

Structural Characteristics

The structural integrity of T Slot Aluminum is largely due to its innovative design. Each profile is engineered to be lightweight yet remarkably strong, making it suitable for a wide range of uses. The slots enable easy attachment of accessories and components without the need for welding or drilling, which significantly reduces labor time and costs. This modularity allows for quick modifications and expansions, making it ideal for projects that require frequent updates or changes.

According to Gabrian International, T Slot Aluminum profiles are available in various sizes and configurations, ranging from single-slot to multi-slot designs. This variety ensures that there is a suitable profile for virtually any project, whether it involves creating a simple frame or a complex industrial structure.

Design Flexibility

The design of T Slot Aluminum is inherently flexible, which is one of its most significant advantages. The 'T' slots allow for the attachment of connectors and other hardware, facilitating the creation of custom solutions tailored to specific needs. This adaptability is particularly beneficial in environments where changes are frequent, such as in manufacturing facilities or workshops. The profiles can be easily disassembled and reconfigured, providing a cost-effective solution for dynamic settings.

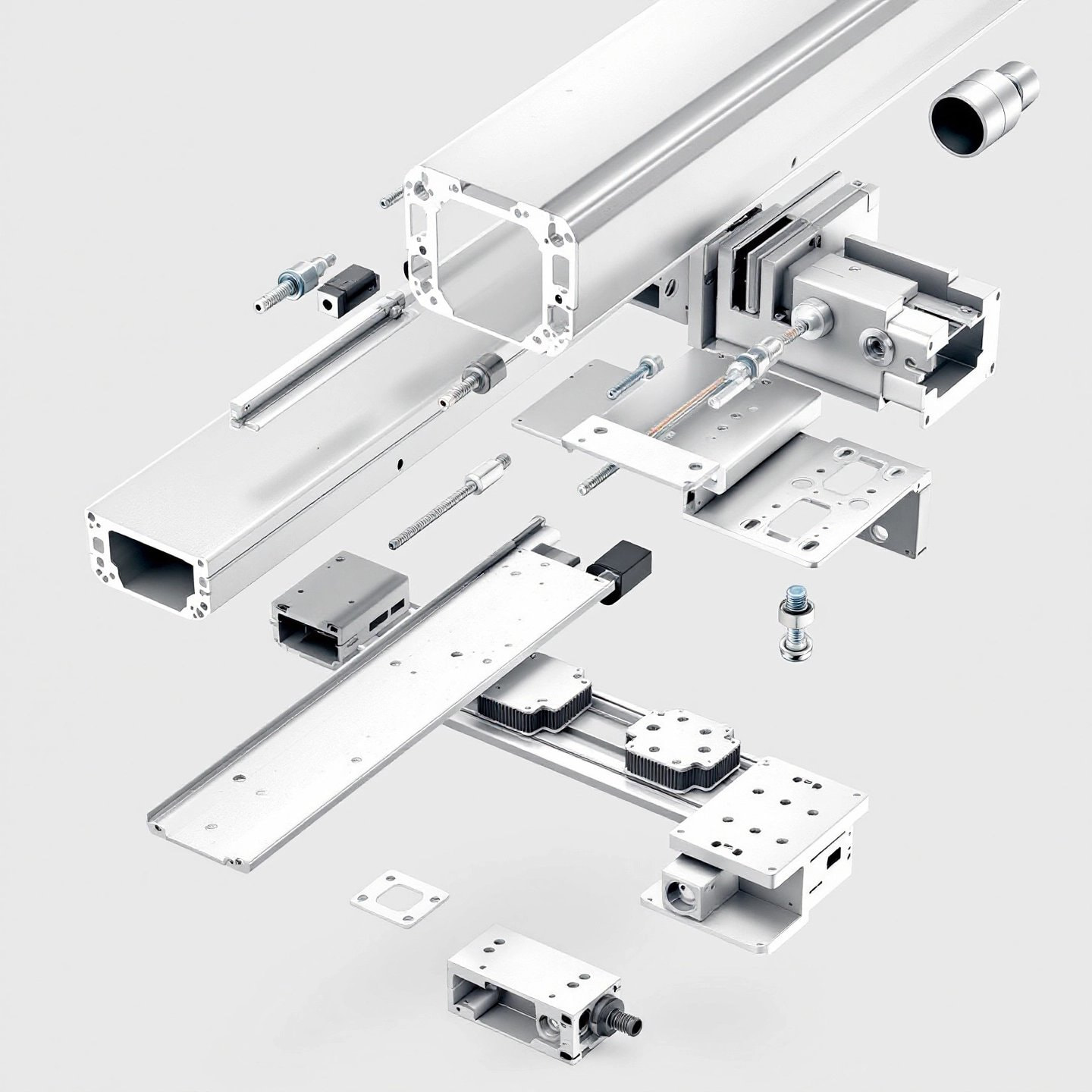

Moreover, the ability to integrate linear motion components, such as slides and carriages, further enhances its utility in applications requiring precise movement control. As noted by Vention, the strength and rigidity of these profiles make them suitable for high-load applications, ensuring reliability even under demanding conditions.

In summary, T Slot Aluminum's unique structure and design offer a versatile and efficient solution for creating custom frames and structures. Its ease of assembly, combined with the ability to modify and expand projects seamlessly, makes it a preferred choice for professionals and hobbyists alike. As we delve deeper into its applications, the true potential of T Slot Aluminum becomes increasingly apparent.

Common Applications of T Slot Aluminum

T Slot Aluminum is celebrated for its versatility, finding applications across a wide range of industries and projects. Its unique properties make it an ideal choice for both industrial and DIY applications, offering solutions that are both functional and aesthetically pleasing. Let's delve into the various ways this material is utilized, highlighting its role in different sectors.

Industrial Applications

In the industrial sector, industrial T Slot Aluminum is often employed to construct machinery and equipment frameworks. Its robustness and ease of assembly make it a preferred choice for building workstations, machine guards, and conveyor systems. The need for welding is eliminated, allowing for quick assembly and disassembly, which is crucial in dynamic industrial environments where modifications are frequent. T Slot Aluminum's ability to create customized solutions enhances productivity and safety, making it indispensable in manufacturing plants and automation systems.

Moreover, its use extends to the automotive and aerospace industries, where it replaces heavier materials like steel. In these sectors, T Slot Aluminum is used for constructing components such as shock absorbers, steering columns, and lightweight aerospace parts. Its strength-to-weight ratio and resistance to deformation make it a reliable choice for high-stress applications.

DIY and Home Improvement Projects

For hobbyists and DIY enthusiasts, T Slot Aluminum offers endless possibilities. Its adaptability allows for the creation of custom furniture, shelving, and even home automation systems. For instance, DIY T Slot Aluminum projects can range from building adjustable desks and tables to creating sophisticated home automation setups like smart mirrors or automated curtains. The ease with which these profiles can be cut and assembled makes them accessible to anyone looking to personalize their living spaces.

Additionally, T Slot Aluminum is a popular choice for constructing utility carts, storage solutions, and window frames. Its corrosion resistance and modular design provide a durable and flexible alternative to traditional materials like wood or plastic. This flexibility is particularly beneficial for those who require custom dimensions or designs that off-the-shelf products cannot offer.

Creative Uses in Specialized Sectors

Beyond standard applications, T Slot Aluminum's adaptability lends itself to creative uses in specialized sectors. For example, in the food and beverage industry, it is used to build sanitary workstations and shelving units. Its non-corrosive nature and ease of cleaning make it suitable for environments where hygiene is paramount.

In conclusion, T Slot Aluminum's diverse applications across various industries underscore its versatility and practicality. Whether used in industrial settings or DIY projects, its ability to provide customized and efficient solutions makes it a valuable material for modern construction and design. As industries continue to evolve, the demand for such adaptable materials is likely to grow, further cementing T Slot Aluminum's role in innovative engineering and design projects.

Comparing T Slot Aluminum with Steel and Wood: Key Advantages (AI-generated)

Comparing T Slot Aluminum with Steel and Wood: Key Advantages (AI-generated)

Advantages of Using T Slot Aluminum

T Slot Aluminum stands out as a highly advantageous material in the realms of construction and manufacturing, thanks to its unique properties that cater to a wide array of applications. Its popularity is largely driven by key benefits that include durability, flexibility, and ease of use, making it a preferred choice for building robust and adaptable structures.

Durability and Strength

One of the primary T Slot Aluminum benefits is its exceptional strength and durability. Made from high-quality aluminum alloys, these profiles can withstand significant weight and stress, ensuring long-lasting performance in demanding environments. The inherent strength of T Slot Aluminum makes it suitable for applications that require high structural integrity, such as in industrial machinery and automation systems.

Flexibility and Customization

The flexibility of T Slot Aluminum is another standout advantage. Its modular design allows for easy assembly and modification, enabling users to create custom solutions tailored to specific needs. This adaptability is particularly beneficial in dynamic environments where frequent changes are necessary. With T Slot Aluminum, components can be easily added, removed, or reconfigured without the need for complex tools or processes, providing a cost-effective and time-efficient solution.

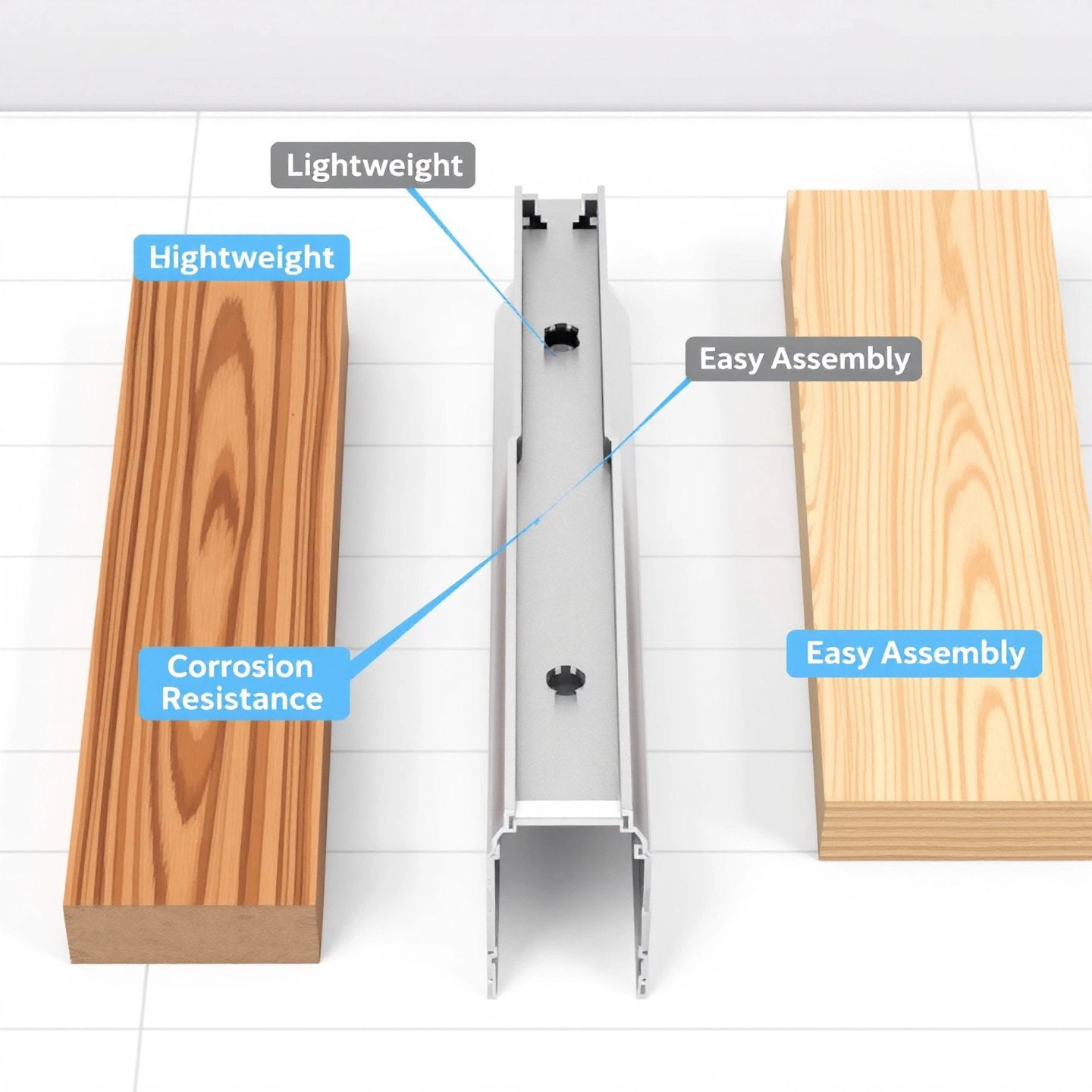

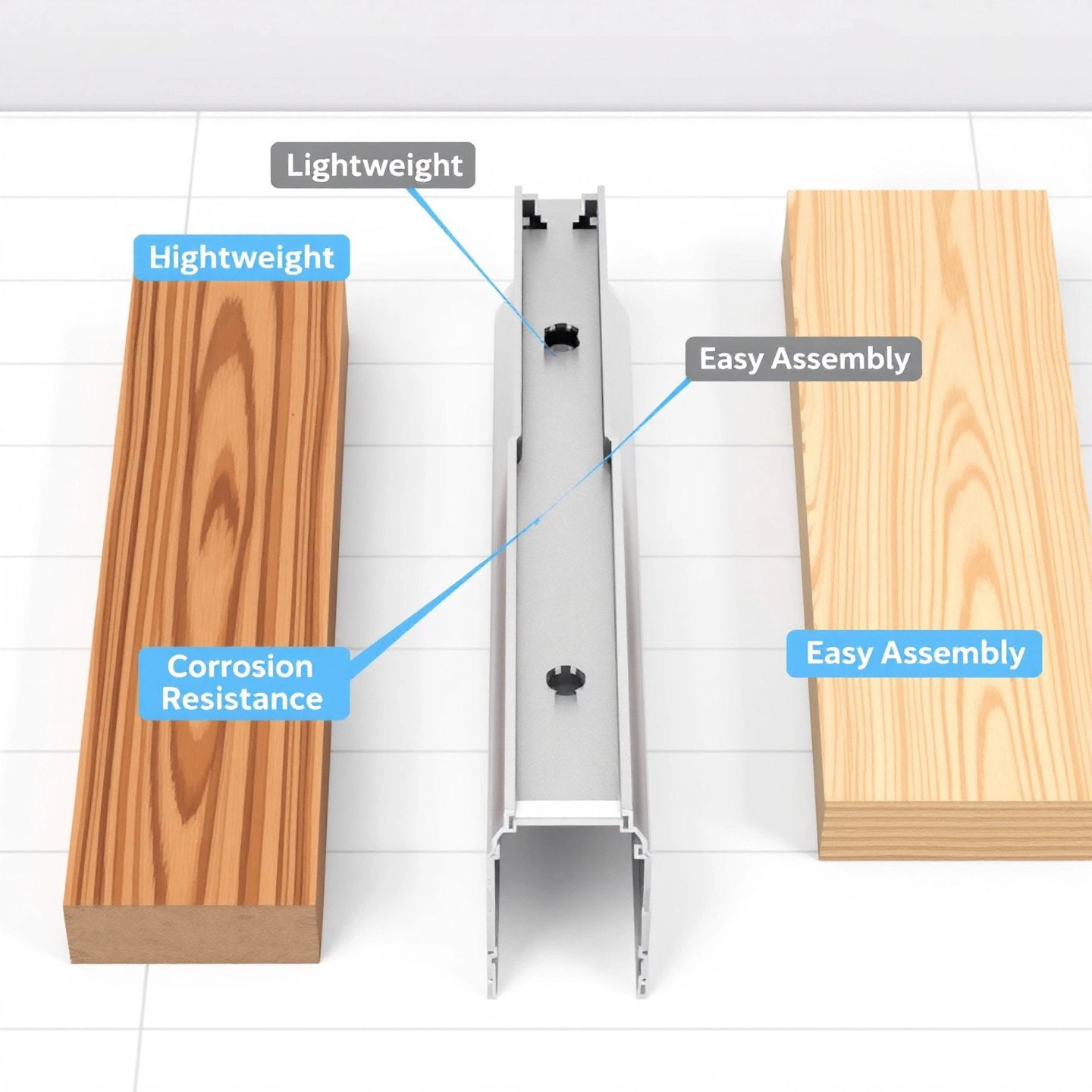

Lightweight and Easy Handling

Compared to traditional materials like steel, T Slot Aluminum is significantly lighter, facilitating easier handling and installation. This lightweight nature not only reduces transportation costs but also simplifies the assembly process, making it accessible for both professional and DIY applications. The ease of working with T Slot Aluminum is a considerable advantage in industries where quick assembly and disassembly are crucial, such as in manufacturing and construction.

Corrosion Resistance and Low Maintenance

T Slot Aluminum's natural resistance to corrosion further enhances its appeal, particularly in environments exposed to moisture or chemicals. Unlike steel, which is prone to rust, T Slot Aluminum maintains its integrity over time, reducing the need for frequent maintenance and repairs. This characteristic makes it an ideal choice for outdoor applications or settings where chemical exposure is common, ensuring longevity and reliability.

In summary, the advantages of T Slot Aluminum, including its durability, flexibility, lightweight nature, and corrosion resistance, make it an invaluable material for a wide range of applications. These benefits not only provide practical solutions but also offer a cost-effective alternative to traditional materials, driving its growing popularity across industries. As we explore further, understanding how T Slot Aluminum compares to other materials will offer deeper insights into its unique value proposition.

Comparing T Slot Aluminum to Other Materials

When selecting materials for construction or manufacturing projects, understanding the differences between T Slot Aluminum and other common materials like steel and wood is crucial. Each material offers distinct advantages and limitations that can significantly impact project outcomes. Let's explore these comparisons to help you make informed decisions.

T Slot Aluminum vs. Steel

Steel has long been a staple in construction due to its high strength and durability. However, T Slot Aluminum presents a compelling alternative, especially when weight is a critical factor. Weighing only about one-third as much as steel, aluminum offers a superior strength-to-weight ratio, making it ideal for applications where reducing weight is essential without compromising strength.

One of the most significant advantages of T Slot Aluminum over steel is its corrosion resistance. Aluminum naturally forms a protective oxide layer, which shields it from environmental degradation, eliminating the need for additional coatings or treatments that steel requires to prevent rust. This makes aluminum a more sustainable and low-maintenance option in environments prone to moisture or chemical exposure.

Moreover, T Slot Aluminum does not require welding, unlike steel, which can lead to cost savings in both labor and materials (JH Foster). The modularity of aluminum profiles allows for easy assembly and modification, which is particularly beneficial in dynamic industrial settings where flexibility is paramount.

T Slot Aluminum vs. Wood

Wood is often chosen for its aesthetic appeal and ease of use, especially in DIY projects. However, T Slot Aluminum offers several advantages that make it a preferable choice for structural applications. Unlike wood, aluminum is not susceptible to warping, rotting, or pest damage, ensuring greater longevity and stability.

Aluminum's dimensional stability means it does not expand or contract with changes in humidity and temperature, unlike wood. This consistency is crucial in precision applications where maintaining exact dimensions is vital.

Additionally, T Slot Aluminum is non-combustible, offering a safer alternative to wood in environments where fire risk is a concern. Its non-flammable nature enhances safety, particularly in industrial and commercial settings (Parco Inc.).

In conclusion, while steel and wood each have their own merits, T Slot Aluminum provides a versatile, durable, and cost-effective option for a wide range of applications. Its lightweight nature, corrosion resistance, and ease of assembly make it a standout choice, especially in projects requiring adaptability and minimal maintenance. As you consider your material options, exploring project cooperation with professional aluminum profile customization manufacturers can further enhance your project's success. Understanding the unique benefits of T Slot Aluminum will enable you to leverage its full potential in creating innovative and efficient solutions.

Guide to Selecting the Right T Slot Aluminum for Your Project (AI-generated)

Guide to Selecting the Right T Slot Aluminum for Your Project (AI-generated)

Buying Guide: Choosing the Right T Slot Aluminum

Selecting the right T Slot Aluminum for your project is a crucial step that can significantly influence the outcome and efficiency of your design. With a plethora of options available, understanding how to choose the appropriate size and profile type, and identifying reputable suppliers, are essential aspects of a successful purchase.

Considerations for Size and Profile Type

The first step in buying T Slot Aluminum is determining the correct size and profile type for your specific application. Profiles are available in various sizes, such as 20, 30, 40, 45, and 50 series, each designed to meet different load-bearing and structural requirements. As noted by Gap Engineering, smaller profiles like the 20 series are ideal for lightweight applications, such as DIY projects or small machinery, while larger profiles like the 50 series are suited for heavy-duty industrial frames and structures.

Consider the load requirements and the environment in which the aluminum will be used. For projects involving dynamic forces or significant loads, opt for stronger profiles and fastening systems. Conversely, for static applications, you might prioritize cost-effectiveness by selecting lighter profiles.

Supplier Reputation and Quality Assurance

Choosing a reliable supplier is paramount to ensure you receive high-quality T Slot Aluminum. Look for suppliers who offer precise machining and cutting services, as this guarantees the profiles will fit perfectly and perform reliably. Reputable suppliers often provide detailed specifications and engineering support, which can be invaluable in complex projects.

It's advisable to partner with suppliers who have comprehensive knowledge of T Slot Aluminum systems, as they can offer guidance on the best components and configurations for your needs. According to Industrial Profile Systems, working with a supplier who offers no-cost engineering services can help avoid common pitfalls and ensure your project runs smoothly.

Understanding Pricing and Cost Considerations

Pricing for T Slot Aluminum can vary based on factors such as profile size, type, and additional machining or customization services. While it might be tempting to opt for the cheapest option, investing in high-quality materials can save costs in the long run by reducing maintenance and replacement needs. Consider the total cost of ownership, including potential savings from reduced assembly time and improved durability.

In conclusion, selecting the right T Slot Aluminum involves careful consideration of size, supplier reputation, and cost. By understanding these factors and working with experienced manufacturers, you can ensure that your project benefits from the versatility and efficiency that T Slot Aluminum offers. As you explore options, consider engaging with professional aluminum profile customization manufacturers, such as Sunmay Aluminum, to leverage their expertise and enhance your project's success.

Conclusion: The Future of T Slot Aluminum

The future of T Slot Aluminum is bright and promising, as it continues to evolve and adapt to the ever-changing demands of various industries. This versatile material is not only meeting current needs but is also paving the way for future innovations that will enhance its applications and efficiency. As industries increasingly prioritize sustainability and technological integration, T Slot Aluminum is set to play a critical role in these developments.

Technological Advancements and Innovations

One of the key drivers of innovation in T Slot Aluminum is the advancement in extrusion technology, which has led to the development of stronger and lighter aluminum alloys. These innovations allow for the creation of structures with enhanced load-bearing capacities while maintaining a reduced weight profile. Additionally, the integration of smart technologies, such as sensors and IoT devices, is revolutionizing the use of T Slot Aluminum by enabling real-time monitoring and control of structures, thus enhancing safety and efficiency in various applications (Parco Inc.).

Sustainability and Environmental Impact

As the world moves towards more sustainable practices, T Slot Aluminum is gaining recognition for its eco-friendly attributes. The material's recyclability and the use of recycled aluminum in production processes significantly reduce its environmental footprint. This aligns with global sustainability goals, making T Slot Aluminum an attractive choice for industries committed to reducing their carbon footprint. Moreover, advancements in extrusion processes are minimizing waste, further enhancing the material's sustainability credentials.

Future Prospects and Industry Integration

Looking ahead, the integration of T Slot Aluminum with emerging technologies such as AI and machine learning is expected to open new avenues for its application. These technologies will enable more efficient design and manufacturing processes, allowing for the creation of highly customized and adaptive structures. As industries continue to embrace digital transformation, T Slot Aluminum will likely become a cornerstone in the construction of smart factories and automated systems.

In conclusion, the future of T Slot Aluminum is poised for significant growth and innovation. By leveraging its inherent strengths and aligning with technological and environmental trends, this material is set to redefine its role in various industries. As you explore opportunities in this evolving landscape, consider collaborating with professional aluminum profile customization manufacturers to fully harness the potential of T Slot Aluminum in your projects.

Explore Quality T Slot Aluminum Solutions

When embarking on projects that require the use of T Slot Aluminum, selecting high-quality solutions from reputable manufacturers is crucial. The right choice can significantly impact the performance, durability, and overall success of your construction or manufacturing endeavors. Quality T Slot Aluminum offers the reliability and precision needed for a wide range of applications, from industrial machinery to intricate DIY projects.

Importance of Choosing the Right Manufacturer

Choosing a reliable T Slot Aluminum manufacturer ensures that you receive products that meet stringent quality standards. Reputable manufacturers, such as Suqian Sunmay Aluminium Company Limited, offer extensive expertise and state-of-the-art technology to produce aluminum profiles that are both high in quality and cost-effective. With their advanced extrusion capabilities, Sunmay Aluminum is able to craft precision-engineered profiles that cater to diverse industry needs, ensuring that your projects are built on a foundation of excellence.

Sunmay Aluminum's commitment to quality is reflected in their adherence to international standards such as GB5237, TS16949, EN12020, EN755, and EN573. This dedication guarantees that their T Slot Aluminum profiles are not only robust but also versatile enough to meet various application requirements. By selecting a manufacturer with a proven track record, you can mitigate risks associated with inferior materials and ensure long-term satisfaction with your projects.

Global Reach and Expertise

With a global presence spanning over 50 countries, Sunmay Aluminum has established itself as a leader in the aluminum industry. Their extensive portfolio includes architectural, industrial, and automotive aluminum solutions, which have been praised by distributors worldwide. This global reach not only underscores their capability to deliver high-quality products but also highlights their ability to support international projects with ease and efficiency.

Moreover, Sunmay Aluminum's expertise in surface treatments, such as anodizing and powder coating, enhances the aesthetic appeal and durability of their T Slot Aluminum profiles. This comprehensive approach to manufacturing ensures that customers receive products that are both functionally superior and visually appealing, making them a preferred choice for discerning clients.

Partnering for Success

Engaging with a professional aluminum profile customization manufacturer like Sunmay Aluminum offers numerous benefits. Their commitment to customer satisfaction and innovative solutions positions them as a valuable partner in your project's success. By choosing Sunmay, you gain access to a wealth of knowledge and resources that can help you navigate the complexities of aluminum profile selection and application.

In conclusion, the importance of selecting quality T Slot Aluminum from a reputable manufacturer cannot be overstated. As you explore options for your next project, consider partnering with industry leaders like Sunmay Aluminum to ensure that you receive the best products and support available. Their expertise and dedication to excellence will not only enhance your project's outcomes but also provide peace of mind knowing that you are working with a trusted supplier.

Frequently Asked Questions about T Slot Aluminum

1. What is T-slot aluminum used for?

T-slot aluminum is used for constructing industrial workstations, machine guards, and DIY projects due to its modular design and ease of assembly.

2. How strong is an aluminum T-slot?

Aluminum T-slot profiles offer significant strength, with tensile strengths reaching up to 38,000 psi, making them suitable for various structural applications.

3. How much weight can an aluminum T-slot hold?

The weight capacity of T-slot aluminum depends on the profile size and application, with some profiles supporting up to 184 lbs over a 36-inch span.

4. What is the difference between T-slot and V-slot aluminum?

T-slot aluminum has a 'T' shaped groove for easy assembly, while V-slot aluminum features a beveled edge, offering different mechanical properties.

5. Why choose T Slot Aluminum over steel or wood?

T Slot Aluminum is lightweight, corrosion-resistant, and easy to assemble, offering a flexible and durable alternative to steel or wood.